Red Panda Network (RPN) leads a number of initiatives that help the local people of eastern Nepal earn income while supporting red panda and forest conservation. In this article, we highlight a sustainable livelihood program called Nettle Fiber Extraction. We interviewed RPN Conservation Coordinator, Sonam Tashi Lama, who explained to us the details of the recent training.

Please discuss what Nettle Fibers are and how they are extracted? Do you use sustainable harvesting techniques?

Sonam: Stinging nettle is a common plant that grows on waste ground, in gardens, at the edges of forests and on riverbanks. Nettle requires fertile soils with high organic matter content which are rich in nutrients and provide adequate water. Nettle fiber is used in the production of textiles. Nettle produces fiber for making textile and clothing. The three main fiber producing species are European Nettle, Ramie and Himalayan Nettle. The fiber comes from the stem and incidentally there is no sting left in the extracted fiber. The upper part of the nettle stem has a higher percentage of fibers and a lower percentage of the woody core than does the lower part. The stem from which the fiber comes from is very long and strong. Nettle Fibers are white silky up to 50mm (2″) long, and produce a fine silky fabric.

The technique used for harvesting nettle is sustainable. The stems are cut only after they are fully matured. The seeds will have fallen off by then so next year a new plant grows on the same place. Fiber can be harvested only once a year.

Describe a typical day for a student in the Nettle Fiber Extraction and Weaving Training program. What specific skills are taught and practiced during training?

Sonam: The stem needs to be cut first and the cut should be near the ground. Gloves are required to be worn during this process. The leaves are then removed from the stalks. The stems are left to dry for a day, this makes the stems flexible and easier to split later that day. The stems are squeezed flat until it splits. The pith is broken and levered off by bending stick over a finger. The woody pith is separated gently.

The inner part of the stem that makes the fiber is then boiled in water and mixed with the required chemical. Ash can be used instead of the chemical which is a cheaper option or if the particular chemical required is not available.

After boiling they are taken and washed in tap water, which removes whatever outer layer is left. After washing it is rubbed in mud called Kamero Mato (in Nepali). It is then left to dry in the sun, after drying it in the sun the fiber is ready to be weaved.

Nettle Fibres after drying

Nettle Fibres after drying

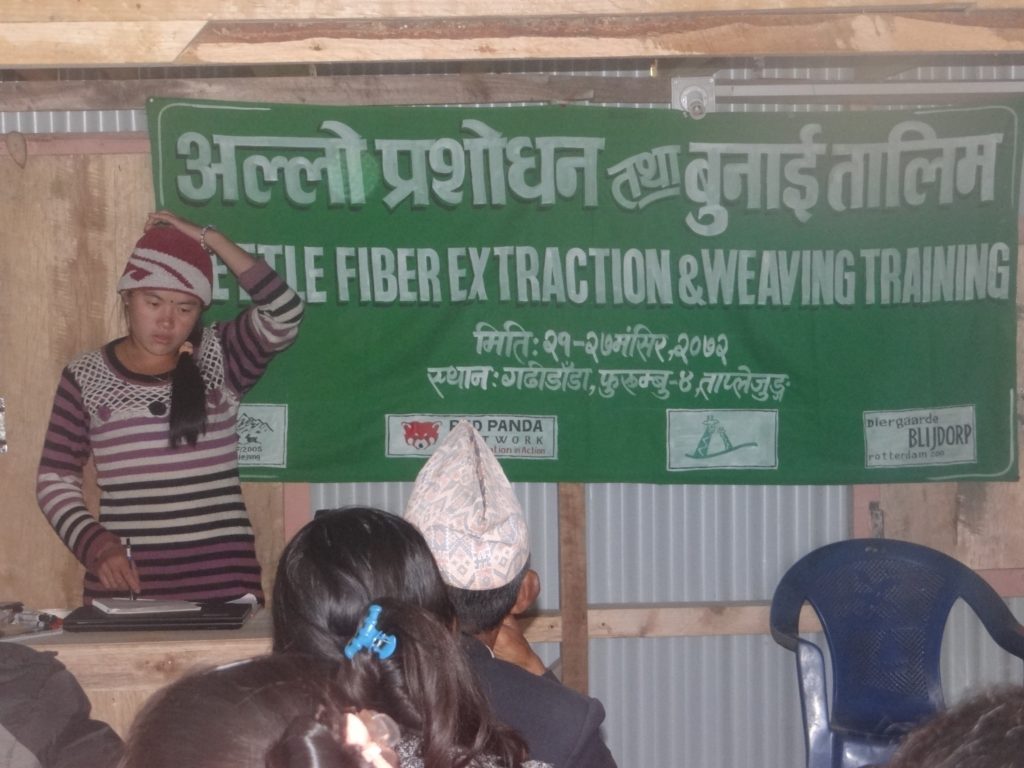

The training was held in Gadi Danda of Phurumbu village in Taplejung district. It went on for 7 days. There were 17 participants (13 women ,4 men) from three villages: Phawa Khola, Phurumbu and Hangdewa.

The participants learn how to make thread out of the nettle. The participants were from 3 VDCs, from Community Forest Users Group namely Phurumbu Khadka, Phatibara Simbu and Bhitri Deorali.

How exactly do the program participants earn income? Is there a store on-site or do participants sell from their homes?

Sonam: We don’t have a store on site. The participants of this training probably won’t be able to earn income until they take the weaving training next year. Then they will be able to sell the items from their own homes.

Tell me about the customer demographics. How do you market your products to the customers?

Sonam: The customers will be the people traveling from local urban areas, as well as tourists who come to Nepal. We will market the products through our social media channels and our online shop once it is up.

Danielle Lippe

Writing and Communications Volunteer

Red Panda Network